If you are a bottled water business owner, you’ll be able to relate to this.

Imagine you received an order for 600 water bottles (50L) on Saturday, which needs to be delivered on Wednesday. Additionally, you forgot to contact your vendor for the procurement of raw materials for plastic bottles (50 L), caps, and labels. This led to delays in production and order fulfillment.

This is where automated replenishment comes into the picture. Water Delivery Solutions (WDS) offers a bottled water ERP that can help you automate your procurement. This system could place purchase orders based on a predefined threshold value. This means you could instruct it to place a purchase order if an item’s stock reaches a certain level. Suppose that the number is 20 for plastic bottles of 50 L; the system will place your order when 20 bottles are left in your inventory.

The blog includes

What is automated replenishment?

Automated replenishment is a supply chain and inventory management process where stock levels are monitored and replenished automatically using software. Instead of manually placing orders when stock is low, the system defines predefined rules, data analytics, and real-time information to trigger purchase orders or stock transfers when inventory falls below a certain threshold.

In the bottled water manufacturing industry, automated replenishment refers to the use of advanced ERP systems to ensure that essential raw materials, including empty bottles, caps, labels, purification chemicals, and packaging materials, are replenished automatically when minimum thresholds are reached. It also includes replenishing finished goods inventory or delivery hubs based on real-time demand and sales forecasts.

How does automated replenishment work?

Automated replenishment includes replenishing raw materials and finished products based on the orders received and forecasted sales. Here is the breakdown on how it works;

Raw material replenishment

When the stock for empty PET bottles, caps, or labels falls below the current level, the system automatically generates a purchase request. Integration with suppliers allows seamless order placement without manual intervention. You can also define placing orders via email. The system can send an automated purchase order through email.

Chemical and purification reagent management

The system can track the usage rates of purification agents and trigger restocking based on batch usage or production volume.

Production-linked reordering

It aligns the replenishment of material with production planning to avoid delays in bottling due to stockouts.

Finished goods inventory control

The system automatically distributes finished water bottles from the manufacturing plant to warehouses or delivery hubs based on sales velocity and sales data.

Why is automated replenishment important?

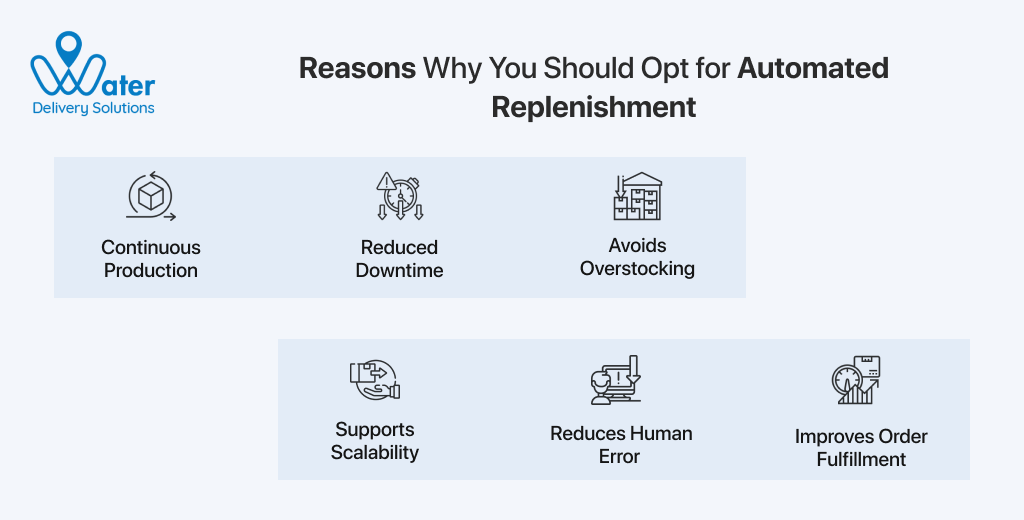

Automated replenishment is critical in bottled water manufacturing, as it ensures the smooth, uninterrupted flow of production and distribution in a highly competitive and demand-sensitive industry. Reasons why you should opt for automated replenishment:

Ensures continuous production

Bottled water production depends on a steady supply of materials like bottles, caps, and purification chemicals. Automated replenishment prevents production stoppage caused by stockouts of these essentials.

Reduced downtime and delays

Manual reordering is prone to human errors and delays. Automated systems eliminate these risks by triggering timely procurement actions, ensuring production lines run without interruption.

Avoids overstocking and waste

Excess raw materials can expire or occupy costly warehouse space. Automated replenishment optimizes stock levels, preventing overordering and reducing storage and spoilage costs.

Improve cash flow

Maintaining optimal inventory, not too much and not too little, businesses can free up working capital and reduce unnecessary inventory investment.

Supports scalable growth

As your bottled water businesses expand operations across regions or into new products, manual replenishment becomes unsustainable. Automation enables consistent inventory management across multiple plants or warehouses.

Reduces human error and labor costs

The system automates repetitive procurement tasks, minimizing the risk of missed orders, calculations, or double-ordering, and frees up staff to focus on higher-value activities.

Improves fulfillment and customer satisfaction

Timely replenishment of finished bottled water at distribution points ensures on-time deliveries and keeps customer satisfaction high, especially for B2B clients with strict delivery schedules.

How does Water Delivery Solutions help automate the replenishment process?

Water Delivery Solutions (WDS) offers an ERP for bottled water businesses that helps automate the replenishment process by centralizing and integrating inventory, procurement, production, and sales data to trigger timely and accurate restocking decisions without manual intervention. Here is how our bottled water ERP helps automate the replenishment process;

Monitors inventory in real-time

The system can track stock levels of raw material (bottles, caps, and labels), chemicals and purification material, and finished bottled water inventory. When any of these dip below the reorder points, the system triggers replenishment actions.

Set reorder rules and safety stock levels.

You can define minimum stock levels, economic order quantities (EOQ), lead times, and supplier preference. The ERP for bottled water businesses uses these parameters to decide when, how much, and from whom to reorder.

Generates automated purchase orders

Once the stock falls below the threshold, the ERP creates a purchase order, sends it directly to the preferred supplier, and tracks delivery schedules and updates inventory upon receipt. This reduces delays and removes the need for manual procurement tasks.

Forecast demand using sales and production data

An advanced bottled water ERP analyzes historical sales trends, upcoming orders, production schedules, and seasonal demand shifts. Using this data, the ERP proactively adjusts replenishment plans to prevent stockouts and overstocking.

Sync procurement with production

The system connects procurement with production to ensure you have enough raw material to meet the production demands. Example: If the production of 50,000 bottles is planned for next week, the ERP checks whether you have enough raw material available and automatically orders what is needed in advance.

Handles multi-location replenishment

If your bottled water business has multiple plants or warehouses or a mobile delivery hub, the ERP can manage replenishment across all the locations. It can balance stock based on consumption rates and location-specific demands.

Alerts and approvals

ERP systems allow workflow-based approvals (purchase manager or procurement head review). They also send notifications for unusual stock movement, supplier delays, or price changes.

Provides analytics and reporting

ERP software offers dashboards and reports to help you track stock turnover rates, order accuracy, supplier performance, and replenishment lead times. This data improves decision-making and helps refine replenishment rules over time.

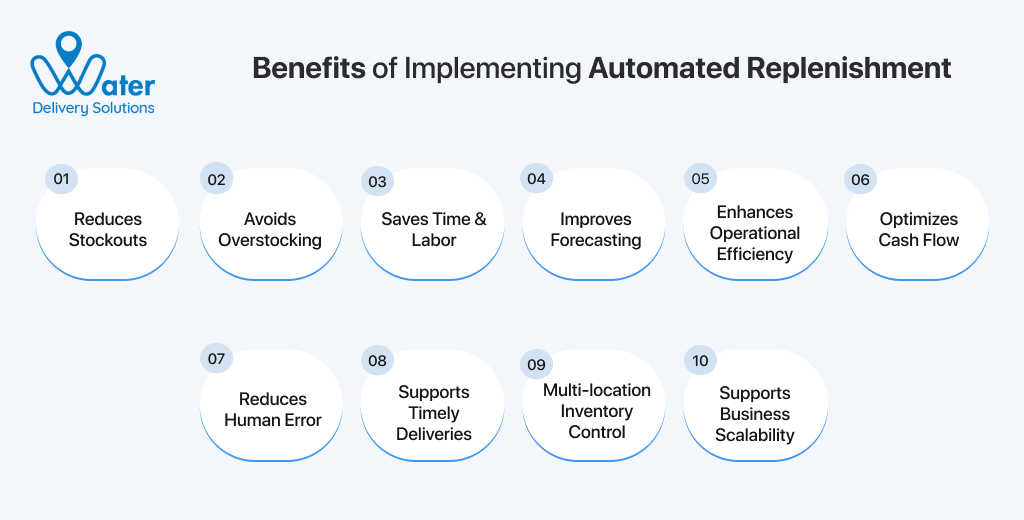

Benefits of implementing automated replenishment

Implementing automated replenishment with the support of ERP systems offers operational, financial, and customer service benefits for bottled water manufacturing, retail, and distribution businesses. The key benefits of implementing automated replenishment are:

Reduces stockouts and production delays

Automated replenishment ensures that all the materials and products are reordered before they run out, keeping manufacturing and delivery operations running smoothly.

Avoids overstocking and excess inventory

Ordering only what is needed based on real-time data and forecasts, businesses reduce the costs of storing unused or slow-moving stock.

Saves time and labor

It eliminates the need for manual tracking and reordering. Staff can focus on higher-value tasks instead of constantly checking inventory and placing purchase orders.

Improves forecasting and planning

Automated systems often use historical sales and usage data to predict future demand, allowing for accurate replenishment based on actual consumption patterns.

Enhances operational efficiency

Replenishment workflows become faster, more consistent, and less prone to human errors. This improves procurement, warehouse, and production alignment.

Optimizes cash flow

Ordering only when needed prevents tying up capital in unnecessary inventory and helps maintain lean operations, improving financial flexibility.

Reduces human error

Manual processing can result in missed orders, duplicate purchases, or wrong quantities. Automation ensures accuracy in inventory tracking and order execution.

Supports timely deliveries

Automated restocking of finished goods ensures that delivery teams or distributors are never short on stock, which is critical for meeting customer demand.

Improved multi-location inventory control

It is ideal for businesses with multiple warehouses or delivery hubs. Stock levels are balanced across locations automatically, reducing regional shortages or surpluses.

Supports business scalability

As operations grow, automation ensures that inventory replenishment doesn’t become a bottleneck, enabling smooth expansion without increasing manual workload.

Conclusion

Automated replenishment is a critical component of modern supply chain management that leverages real-time data, predefined rules, and intelligent forecasting. This helps businesses maintain optimal stock levels, reduce manual errors, and ensure uninterrupted operations. As businesses continue to prioritize agility and scalability, implementing automated replenishment becomes a competitive necessity.

At Water Delivery Solutions (WDS), we offer a comprehensive ERP software specifically designed to cater to the unique demands of bottled water businesses. Schedule a meeting to discuss your business scope and see how we can help.

He loves to explore. His passion for helping delivery industries in all aspects flows through in the vision he has. In addition to providing smart solution to make delivery process flawless, Ravi also likes to write sometimes to make it easier for people from business industry looking for digital solutions.