The bottled water industry is evolving faster than ever, driven by the rising consumer demand, stricter quality regulations, and increasing competition. Manufacturers are under constant pressure to produce high volumes with consistent quality, manage complex supply chains, and deliver orders on time, while keeping costs under control. Achieving all this with traditional systems or manual processes is no longer sustainable.

This is where our ERP for bottled water businesses steps in. Water Delivery Solutions (WDS) offers modern ERP solutions that unify production, quality control, inventory, sales, distribution, and finance into a single platform.

The role of ERP in the bottled water manufacturing business

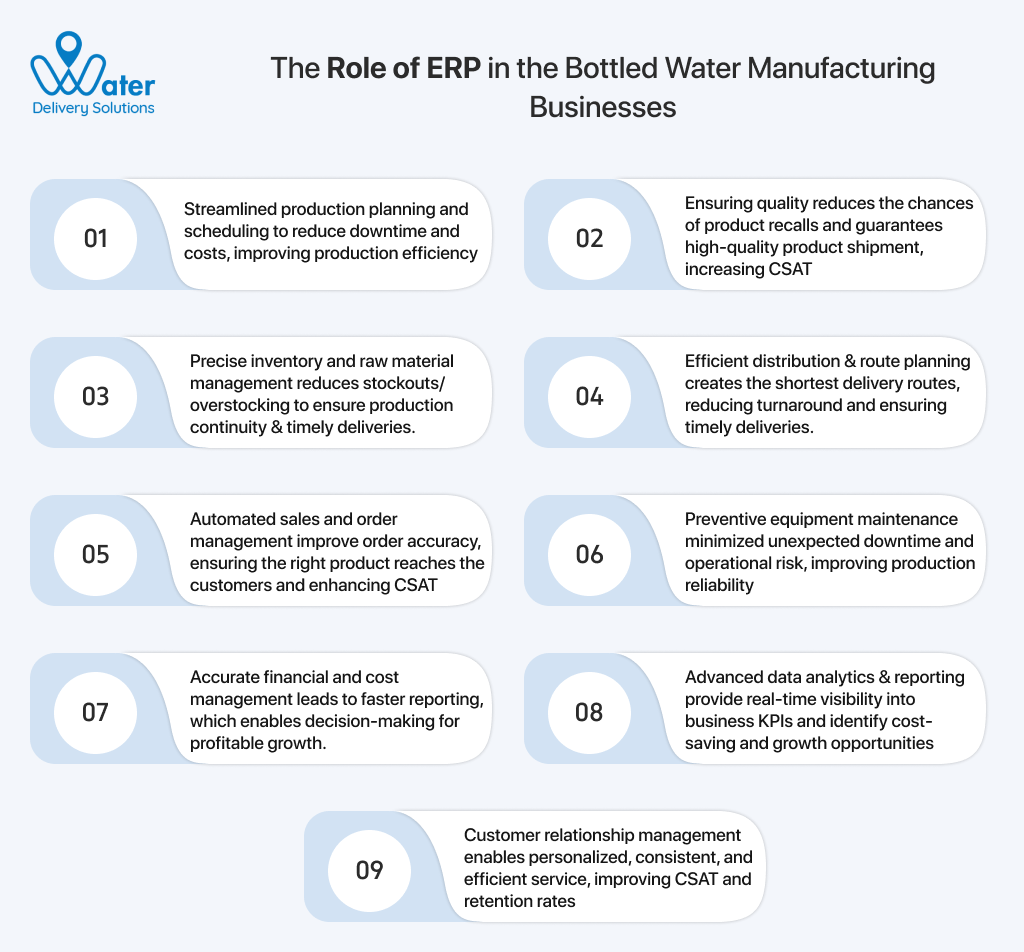

The bottled water ERP integrates all your business operations, enabling you to manage them from a unified system. This provides real-time data across departments, empowering bottled water manufacturing businesses to operate with greater efficiency, ensure compliance, respond quickly to market changes, and make decisions backed by data, not guesswork. The role of ERP in the modern bottled water manufacturing business:

Streamlined production planning and scheduling to reduce downtime and costs, improving production efficiency

Production efficiency depends on synchronizing raw material availability, machine capacity, workforce shifts, and fluctuating customer demand. An ERP system centralizes all these factors into one platform, enabling bottled water manufacturers to create optimized production schedules in minutes instead of hours. It utilizes real-time data from inventory, sales orders, and machine performance to determine the ideal batch sizes, allocate resources, and sequence production runs to minimize downtime. It can also adjust plans dynamically, such as increasing output when demand rises or rescheduling tasks when a machine goes offline. The benefits of streamlined production planning and scheduling are:

- Faster response to changing demand

- Reduced disruptions and idle time

- Better labor and machinery utilization

- Lower operational costs due to improved efficiency

Ensuring quality reduces the chances of product recalls and guarantees high-quality product shipment, increasing CSAT

Maintaining consistent quality and meeting strict regulatory standards is non-negotiable. An ERP system implements quality control into every stage of production, from sourcing raw water to bottling and packaging, ensuring that no product leaves the facility without passing all required checks. You can assign a lot number, which allows complete traceability of materials, test results, and production conditions. Quality testing data, including pH levels, mineral composition, and microbial analysis, is recorded into the system, creating a digital audit trail for internal reviews or regulatory inspections.

Compliance management ensures that the manufacturing aligns with beverage safety regulations, environmental laws, and industry certifications (ISO, BIS, or FDA standards). The ERP can also trigger alerts if any parameter falls outside set limits, prompting immediate corrective action before defective products reach customers. The benefits of ensured quality and compliance are:

- Consistent product quality across all batches

- Faster, more accurate regulatory reporting

- Reduced risk of recalls and penalties

- Increased consumer trust and brand credibility

Precise inventory and raw material management reduces stockouts/overstocking to ensure production continuity & timely deliveries.

Maintaining the right balance of raw material (bottles, caps, labels, and shrink wraps) and finished goods is critical to ensure smooth operations without tying up excess capital. An ERP system gives real-time visibility into stock levels across production plants, warehouses, and distribution centres, enabling precise inventory control. Integrating the inventory module with other modules, including sales, procurement, and production, allows the ERP system to analyze historical data, seasonal trends, and promotional activities to forecast demand. This enables the system to trigger automated purchase orders when the raw material levels approach the reordering point, ensuring uninterrupted production.

ERP tracks your suppliers’ performance, lead time, and delivery reliability, helping manufacturers choose the most dependable vendors. It also coordinates inbound raw material with production schedules and outbound shipments, reducing shortage costs and improving delivery times. The benefits of inventory and supply chain optimization are:

- Prevents stockouts and production delays

- Reduces excess inventory and holding costs

- Improves supplier collaboration and reliability

- Ensures timely deliveries to distributors and retailers

Efficient distribution & route planning creates the shortest delivery routes, reducing turnaround and ensuring timely deliveries.

An ERP for bottled water bridges the gap between sales, production, and logistics, ensuring that every confirmed order flows seamlessly into the manufacturing and delivery pipeline. With all the channels, including distributors, retailers, corporate contracts, and direct-to-consumer platforms, linked to the ERP, the system provides real-time inventory available to the sales team. This prevents over-promising and ensures customers receive accurate delivery times. Once the order is confirmed, the system automatically allocates stock, schedules production, and coordinates with the distribution team to dispatch products.

For route-based deliveries, the bottled water ERP can integrate with GPS-enabled logistics tools to optimize delivery routes, track vehicles, and manage bottle returns for refillable operations. It also automates invoicing and payment tracking, offering sales and finance teams complete visibility over the order-to-cash cycle. The benefits of sales and distribution integration are:

- Faster and more accurate order fulfillment

- Reduced delivery errors and missed deadlines

- Better visibility into sales performance and customer demand patterns

- Improved coordination between sales, production, and logistics teams

Automated sales and order management improve order accuracy, ensuring the right product reaches the customers and enhancing CSAT

Managing a high volume of orders from multiple channels, including wholesalers, retailers, corporate clients, and direct customers, can be complex and ineffective if handled manually. An ERP system automates the entire sales and order management process, reducing delays, eliminating duplication, and improving accuracy. Orders are placed through sales representatives, an e-commerce platform, or a distributor portal. The system automatically validates product availability, applies the correct pricing, and reserves the required stock. It then triggers the next steps, generating invoices, scheduling deliveries, and updating inventory levels in real-time.

For recurring or subscription-based bottled water deliveries, the ERP automatically generates repeat orders, sends reminders, and processes renewals without intervention. It also keeps track of order history and customer preferences, allowing personalised offers and better customer relationship management. The benefits of automating sales and order management are:

- Faster order processing and fulfillment

- Reduced manual errors and missed orders

- Improved customer experience with timely deliveries

- Better visibility into sales trends for strategic planning

Preventive equipment maintenance minimized unexpected downtime and operational risk, improving production reliability

Multiple machines are used in the bottled water manufacturing business, including filtration units, bottling machines, labeling systems, and conveyors. These machines must run reliably to maintain consistent production output. Unplanned breakdowns can halt operations, delay deliveries, and increase maintenance costs. The ERP system enables predictive maintenance scheduling based on time intervals, machine usage, or performance data. It stores complete service histories for each asset, tracks spare parts inventory, and integrates with IoT sensors or machine monitoring tools to detect any early signs of wear and tear (increased vibration, unusual temperature spikes, or slower cycle times).

The system automatically generates maintenance alerts before minor issues become costly failures. Proactive maintenance planning during low-demand periods or scheduled downtime helps manufacturers to avoid disruptions in production schedules while extending the lifespan of machinery. The benefits of preventive equipment maintenance are:

- Minimizes unexpected breakdowns and costly emergency repairs

- Improves production reliability and uptime

- Extends equipment lifespan and return on investment

- Reduces operational risks caused by machine failures

Accurate financial and cost management leads to faster reporting, which enables decision-making for profitable growth.

An ERP system centralizes all financial data, from procurement expenses and production costs to sales revenue and logistics spending, providing a clear, real-time picture of the business’s monetary health. It automates core accounting functions, such as accounts payable, accounts receivable, bank reconciliation, and tax compliance. It integrates directly with the production and inventory modules, taking into account raw materials, labour, utilities, packaging, and distribution costs, allowing businesses to calculate the true cost per bottle.

The system also generates detailed financial reports, profit-and-loss statements, and cash flow forecasts, enabling management to spot trends, control unnecessary spending, and allocate budgets more effectively. With multi-currency and multi-location support, ERP is especially valuable for bottled water businesses operating across different regions. The benefits of accurate financial and cost management are:

- Real-time visibility into financial performance

- Accurate cost analysis for better pricing and budgeting

- Faster and error-free financial reporting

- Improved decision-making for profitability and growth

Advanced data analytics & reporting provide real-time visibility into business KPIs and identify cost-saving and growth opportunities

Water Delivery Solutions (WDS) offers a bottled water ERP with advanced analytics and reporting capabilities, transforming raw operational data into actionable intelligence for strategic decision-making. It can consolidate data from sales, production, inventory, quality control, and finance, and create intuitive dashboards and visual reports that provide decision-makers with a real-time view of business performance. These analytics can uncover patterns such as seasonal demand spikes, top-selling bottle sizes, or recurring production efficiencies.

The ERP system supports predictive and prescriptive analytics, helping manufacturers forecast demand, anticipate supply chain disruptions, and identify opportunities for operational improvements. Automated reporting ensures that your stakeholders, from plant managers to executives, have accurate, up-to-date data information without the need for manual data compilation. The benefits of advanced data analytics and reporting in ERP are:

- Real-time visibility into business KPIs

- Forecasting and trend analysis for proactive decision-making

- Identification of cost-saving and revenue-growth opportunities

- Automated, error-free reporting for faster strategic planning

Customer Relationship Management enables personalized, consistent, and efficient service, improving CSAT and retention rates

The bottled water manufacturing business’s long-term success depends not only on product quality but also on building and maintaining strong relationships with customers (distributors, retailers, corporate clients, or direct consumers). The ERP for bottled water businesses has integrated customer relationship management (CRM) capabilities that centralize all customer-related information, enabling you to deliver personalized, consistent, and efficient service. The system tracks order histories, buying patterns, delivery preferences, and communication records for each customer. This allows your sales team to anticipate needs, recommend suitable products, and manage recurring or subscription-based deliveries.

Automated reminders for contract renewals, payment follow-ups, and promotional offers ensure customers feel valued and engaged. The system also handles complaints and service tickets, directing them to the appropriate teams and monitoring resolution times, thereby enhancing customer satisfaction and loyalty. With data-driven insights from the CRM, bottled water businesses can segment their customer base, run targeted marketing campaigns, and identify high-value accounts for special attention. The benefits of customer relationship management in ERP for the bottled water businesses are:

- Improved customer satisfaction and retention

- Streamlined management of recurring orders and subscriptions

- Better targeting for promotions and upselling opportunities

- Faster resolution of service issues with complete case histories

Conclusion

Implementing an ERP system in your bottled water manufacturing business brings all the moving parts of manufacturing under one unified platform. This ensures smooth production, optimized inventory, maintained compliance, and timely and consistent customer service. An ERP system enables you to combine quality with speed, which is essential in this competitive market.

Water Delivery Solutions (WDS) offers ERP software for bottled water businesses, which is an end-to-end solution for all operations, from production planning to advanced analytics and strengthening customer relationships. This system can help you reduce costs, enhance operational visibility, and respond quickly to changing market demands. If you are a bottled water manufacturer and are looking to improve your business’s efficiency, productivity, and profitability, book a demo.

He loves to explore. His passion for helping delivery industries in all aspects flows through in the vision he has. In addition to providing smart solution to make delivery process flawless, Ravi also likes to write sometimes to make it easier for people from business industry looking for digital solutions.