The bottled water industry is one of the fastest-growing segments in the global beverage market. However, it also faces intense competition, strict quality regulations, and the constant challenge of meeting fluctuating demand. In such a dynamic market environment, operational efficiency, cost control, and compliance are essential for survival and growth.

This is where an ERP system for bottled water manufacturers steps in. Water Delivery Solutions (WDS) offers a bottled water ERP system that integrates every aspect of bottled water manufacturing, from sourcing raw materials to delivering the final products. This article discusses the key features of an ERP tailored for the bottled water manufacturing business.

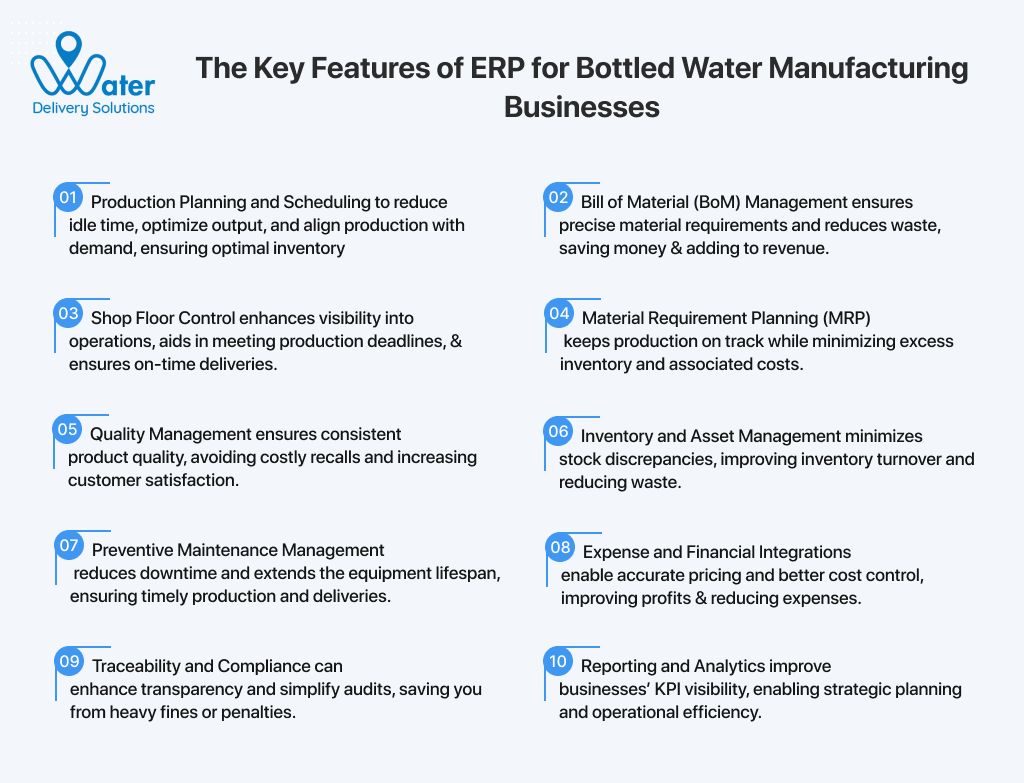

The key features of ERP for bottled water manufacturing businesses

The ERP system is a centralized platform that offers advanced features and functionalities to automate manufacturing processes, increase visibility, and make better decisions. The system aims to boost productivity, maintain consistent quality, and stay ahead of market demands. The features of ERP for bottled water manufacturing businesses are:

Production planning and scheduling to reduce idle time, optimize output, and align production with demand, ensuring optimal inventory

In the bottled water manufacturing industry, demand can fluctuate due to seasons, promotions, or large corporate orders; effective production planning is crucial to prevent both shortages and overproduction. The system considers real-time data from sales forecasts, current inventory levels, machine capacity, and workforce availability, enabling you to create accurate production schedules.

Aligning production closely with actual demand can help reduce idle machine time, prevent overstocking, and ensure raw materials, including bottles, caps, and labels, are available when needed. It can also automatically adjust schedules in response to changes, such as urgent bulk orders or machine maintenance requirements. The benefits of production planning and scheduling features of the ERP’s manufacturing module are:

- Minimizes downtime and production delays.

- Matches output to actual demand for better inventory control.

- Improves resource allocation and production efficiency.

- Responds quickly to market and operational changes.

Bill of Material (BoM) management ensures precise material requirements and reduces waste, saving money & adding to revenue.

Every product, from a 250ml to a 20-litre jar, requires a precise combination of materials, including bottles, caps, labels, shrink wraps, and pallets. Bill of Materials (BoM) management in the ERP system defines these exact material requirements for each product variant, ensuring that the production team always knows what’s needed and in what quantities. The ERP maintains multiple BoM versions to handle different product sizes, flavors (if applicable), or packaging formats, eliminating guesswork and preventing costly mistakes.

The system automatically pulls the required material from inventory when an order is created, ensuring the right components are available at the right time. This helps reduce material overuse, prevent shortages, and optimize procurement, reducing waste and increasing profits. The benefits of the BoM feature of ERP’s manufacturing module are:

- Ensures accurate material planning for every product type.

- Reduces waste and unnecessary inventory costs.

- Eliminates delays from missing components to speed up production.

- Controls material usage to improve profit margins.

Shop floor control enhances visibility into operations, aids in meeting production deadlines, & ensures on-time deliveries.

The production lines run at high speed, and orders are time-sensitive in the bottled water business. Even small delays can disrupt production schedules, leading to missed deliveries. The shop-floor control in an ERP system provides real-time visibility into every stage of production, from water purification to bottling, capping, labeling, and packaging.

Using the shop floor control, production supervisors can monitor work-in-progress (WIP), track machine performance, and view operator activity as it happens. This data can come from manual input or IoT-connected sensors on the production line. If an issue arises in production, the system immediately alerts the team, allowing for prompt corrective action. Closely monitoring production, the shop floor control helps ensure that bottling schedules stay on track and customer orders are fulfilled on time. The benefits of shop floor control in bottled water manufacturing are:

- Provides real-time production tracking and visibility.

- Improves response time to issues or bottlenecks.

- Ensures adherence to production schedules and deadlines.

- Supports consistent on-time deliveries to customers.

Material Requirement Planning (MRP) keeps production on track while minimizing excess inventory and associated costs.

Smooth bottled water manufacturing relies on having the necessary raw materials available, including bottles, caps, labels, and packaging. Material Requirement Planning (MRP) in an ERP system analyzes production schedules, current inventory levels, and supplier lead time to calculate these needs.

It can automatically generate purchase orders or transfer requests when stock levels drop below defined thresholds, preventing costly production stoppages. Simultaneously, it also helps avoid over-purchasing, which can tie up capital and cause storage issues. MRP ensures that the production line stays supplied without accumulating unnecessary excess. The benefits of MRP in bottled water manufacturing are:

- Prevents material shortages that could halt production.

- Minimizes excess inventory and associated carrying costs.

- Optimizes purchasing schedules to improve cash flow.

- Precise demand forecasting to keep production aligned with demand.

Quality management ensures consistent product quality, avoiding costly recalls and increasing customer satisfaction.

Regulatory compliance and consumer trust in the production of bottled water depend heavily on quality management. It embeds quality checks throughout the production process, from water purification to final packaging, ensuring that every bottle meets the required standards. The system can inspect certain key stages, including source water testing, filtration efficiency, bottle sanitization, and seal integrity. It records test results in real-time, flags any deviations from quality specifications, and triggers corrective actions before defective products ship from the facility.

This offers a proactive approach to prevent large-scale issues, such as contamination or faulty sealing, which could lead to costly recalls and reputational damage. Consequently, consistent quality can boost customer satisfaction and brand loyalty in a competitive bottled water market. The benefits of quality management in bottled water manufacturing are:

- Ensures compliance with industry health and safety standards.

- Detects and resolves quality issues early in the process.

- Reduces risk of recalls and related costs.

- Builds trust and loyalty through consistent product quality.

Inventory and asset management minimizes stock discrepancies, improving inventory turnover and reducing waste.

Inventory and warehouse management in an ERP provides real-time visibility into stock levels, locations, and movement across the facility. The system can track every item, whether it is raw materials or finished goods, using batch numbers, barcodes, or RFID tags. This minimizes stock discrepancies by ensuring that every inbound, outbound, and internal movement is recorded accurately.

The bottled water ERP helps maintain optimal inventory turnover by identifying slow-moving stock and triggering replenishment only when necessary. Bottled water has a limited shelf life, and an ERP system can help you implement inventory management strategies, such as FIFO or FEFO, to reduce waste due to expiration. The benefits of inventory and warehouse management in bottled water manufacturing are:

- Reduces stock discrepancies through real-time tracking.

- Aligns stock with demand to improve inventory turnover.

- Supports FIFO/FEFO to minimize waste due to expired product.

- Lowers carrying costs through optimized stock levels.

Preventive maintenance management reduces downtime and extends the equipment lifespan, ensuring timely production and deliveries.

Bottled water production lines operate at high speeds and utilize equipment such as blow moulding machines, water purification systems, filling lines, capping units, and labelling machines. Any unexpected breakdown can halt operations, cause delivery delays, and increase repair costs. Preventive maintenance management can schedule regular inspection and maintenance activities before breakdowns occur in the bottled water ERP system, avoiding these costly disruptions.

The system can track each machine’s usage hours, production cycles, and service history. Based on manufacturer guidelines or operational data, it can generate automated maintenance schedules and alerts for tasks like filter replacement, lubrication, or calibration. This proactive approach ensures that equipment operates at peak efficiency and has a longer service life. It helps reduce unplanned downtime, preventive maintenance supports consistent production output, and helps meet delivery deadlines, while also lowering emergency repair expenses. The benefits of preventive maintenance management in bottled water manufacturing are:

- Minimizes unplanned production stoppages.

- Extends the lifespan of expensive manufacturing equipment.

- Improves production reliability and on-time delivery rates.

- Reduces overall maintenance and repair costs.

Costing and financial integrations enable accurate pricing and better cost control, improving profits & reducing expenses.

Profit margins in bottled water manufacturing can be tight due to competition, fluctuating raw material costs, and high operational expenses. Costing and finance integration in an ERP system provides manufacturers with clear, real-time insights into their actual production costs, allowing them to set accurate prices, control expenses, and increase profitability. It can track all costs throughout the operation, including raw materials (like bottles, caps, and labels), utilities (water and electricity), labor, maintenance, and logistics. It links this data with financial modules, ensuring that every transaction, including purchases, production runs, or shipments, is reflected in the accounting records.

This integration enables cost breakdowns for each product line or batch, making it easier to identify where expenses are rising and take corrective action. It provides precise cost data, which helps businesses to adjust pricing strategies, negotiate better supplier terms, and invest in efficiency improvements without guesswork. The benefits of the costing and finance integration in bottled water manufacturing are:

- Provides accurate, real-time cost tracking per product or batch.

- Integrates financial data for seamless accounting and reporting.

- Supports informed pricing and budgeting decisions.

- Helps identify and eliminate unnecessary expenses.

Traceability and compliance can enhance transparency and simplify audits, saving you from heavy fines or penalties.

Traceability and compliance in an ERP system ensure that every step of production is documented, transparent, and easily verifiable, helping manufacturers to meet these requirements and avoid costly fines or product recalls. With ERP traceability, each batch of bottled water is linked to detailed records about its raw materials, production date, equipment used, quality test results, and distribution path.

If an issue arises, such as contamination detection in a specific lot, the system enables quick identification and targeted recalls rather than pulling large amounts of unaffected stock. Compliance features also maintain up-to-date documentation for audits, certifications, and regulatory reporting. This means less manual paperwork and faster, smoother inspections from health and safety authorities. The key benefits of traceability and compliance in bottled water manufacturing are:

- Enables rapid product recalls with minimal disruptions.

- Maintains accurate records for health and safety compliance.

- Reduces audit preparation time and efforts.

- Minimizes risk of fines, penalties, or reputational damages.

Reporting and analytics improve businesses’ KPI visibility, enabling strategic planning and operational efficiency.

The success of a bottled water manufacturing business depends on timely decisions backed by accurate data. Reporting and analytics in an ERP system provide managers with a clear view of the company’s key performance indicators (KPIs), allowing them to identify trends, identify inefficiencies, and plan strategically. It collects real-time data from across operations, including production rates, inventory levels, sales figures, maintenance schedules, and quality checks, and turns them into actionable reports and visual dashboards.

This makes it easier to track performance against goals, detect bottlenecks, and make informed adjustments before small issues grow into costly problems. Analytics tools can forecast future demand, stimulate “what-if” production scenarios, and analyze cost trends, enabling smarter long-term planning. The benefits of reporting and analytics in bottled water manufacturing are:

- Real-time visibility into operational and financial KPIs.

- Data-driven decisions that improve efficiency and profitability.

- Predictive insights for demand planning and resource allocation.

- Customizable dashboards and reports for different departments.

Conclusion

The success of your bottled water industry depends on your operational efficiency, product quality, and the ability to adapt quickly to market changes. An ERP system for bottled water manufacturing is a central tool that connects production, inventory, quality control, sales, and finance into one cohesive operation. Each ERP feature, from production planning to real-time reporting, works together to eliminate bottlenecks, ensure compliance, and boost profitability.

Water Delivery Solutions (WDS) offers comprehensive bottled water ERP software that integrates all your business processes, from procurement and production to quality control, packaging, and distribution. It automates your business operations, provides complete operational visibility, and ensures high-quality products. It aims to improve your business efficiency, productivity, and profitability. If you are in a water bottling or bottled water manufacturing business, book a demo to see how we can help streamline your business and improve your ROI.

He loves to explore. His passion for helping delivery industries in all aspects flows through in the vision he has. In addition to providing smart solution to make delivery process flawless, Ravi also likes to write sometimes to make it easier for people from business industry looking for digital solutions.